Dynamics Performance Analysis

This document contains information regarding the tools provided by Vortex® Studio to help find dynamics performance issues. Please refer to the Performance Analysis guide for an overview.

Finding Bottlenecks in the Physics Engine

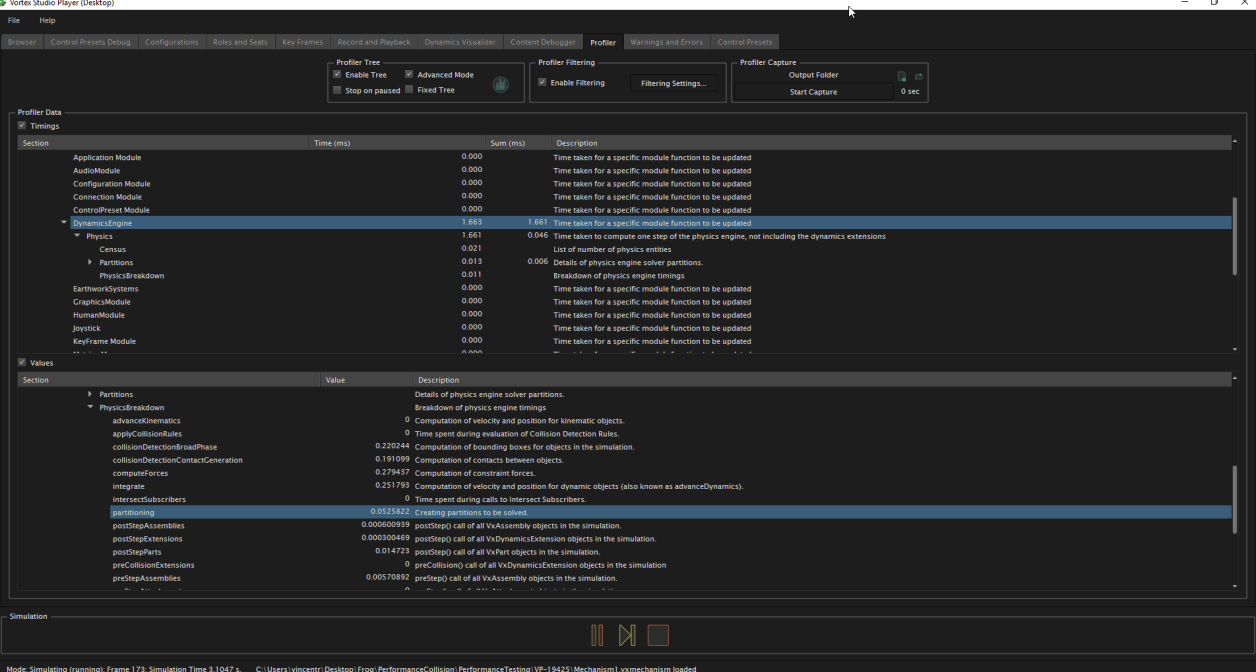

If The Profiler tab in the Vortex Studio Player indicates excessive time consumption in the dynamics module (usually called DynamicsEngine in your application setup) you can modify your simulation content or tune simulation parameters to reduce the time spent.

In order to see if the dynamics module is the bottleneck, enable the Timings option in the Profiler panel and examine the time spent by the DynamicsEngine in the Timings section by navigating to ApplicationUpdate > ModulesUpdate > DynamicsEngine.

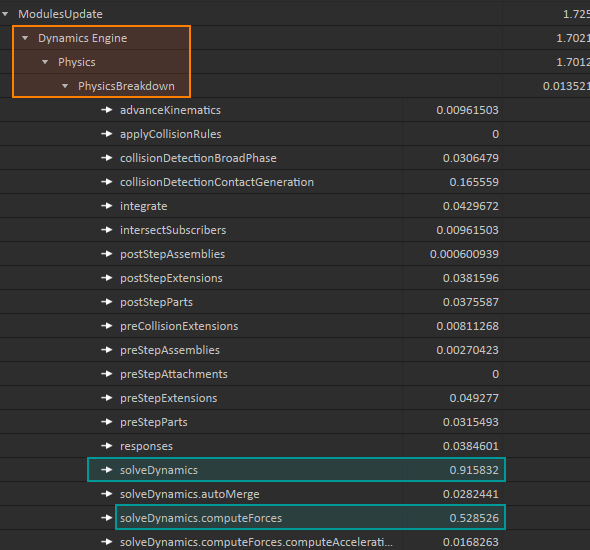

For a breakdown of the time spent, enable the Values option and navigate to ApplicationUpdate > ModulesUpdate > DynamicsEngine > Physics > PhysicsBreakdown. The image below shows the detailed timings of the individual components in the physics engine pipeline.

High Time Consumption in "solveDynamics.computeForces"

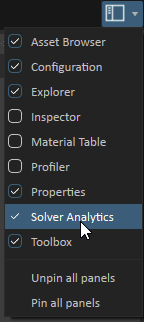

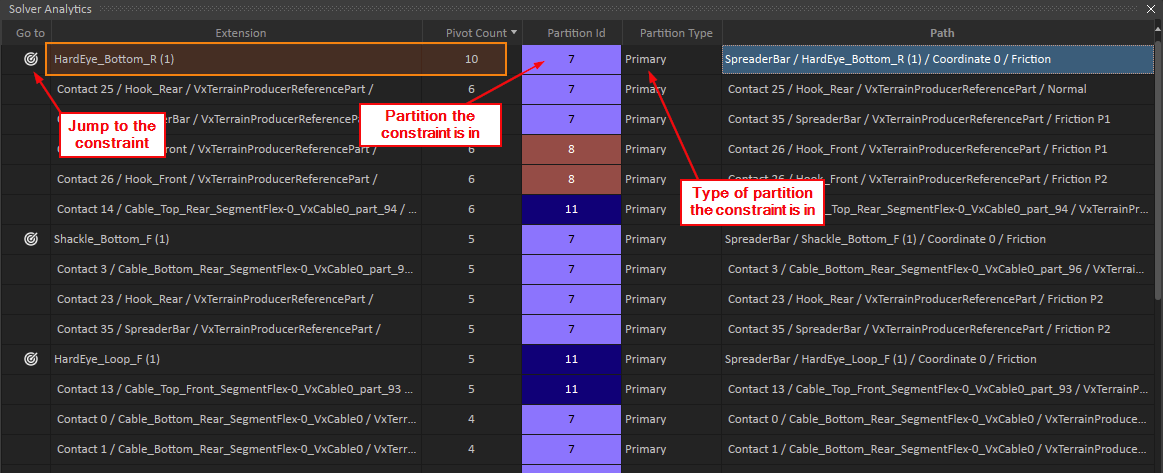

Use the Solver Analytics panel to make the problem easier to solve

Split the problem and parallelize the work

Make sure that inactive simulation components can fall asleep

Use techniques to reduce time consumption when simulating long and detailed flexible cables

High Time Consumption in "collisionDetectionBroadPhase"

The first step in the physics pipeline is the broad phase. The broad phase computes the potential intersections between collision geometries. It is rarely the source of the bottleneck, but it can happen when a large number of collision geometries are present in the scene. A good way to improve the broad phase is to use composites for the collision geometries which are in the same part. At the broad phase level, all the collision geometries that would be in the same composite will be processed as only a single bounding volume. This will reduce the time consumption for the broad phase but will also have an impact on the contact generation. This impact is due to the so-called contact simplification process, which will consider the composite as a single collision geometry and will reduce the number of contacts accordingly.

Time Time Consumption in "collisionDetectionContactGeneration"

In the Profiler, under Physics > Census, Enabled Contacts reveals the number of available contacts. If the number is quite high, this could be the source of the performance problem. There are several ways to deal with this issue:

- Using collision rules can considerably reduce undesired or useless contacts.

- Using meshes with a high level of detail can be computationally expensive for the collision detection. You can try splitting your mesh into multiple convex meshes using the Convex Mesh Decomposition feature.

- Optimize the middle phase in the collision detection of your Terrain using the UV Grid Visualizer, which is an extension that help you to tune the terrain parameters.

- Many contacts are still enabled because rigid bodies are not sleeping. See Setting Sleep Thresholds of Parts for more information.

- An interaction between two rigid bodies generates too many contacts. By putting the collision geometries into a composite collision geometry, the number of contacts will be reduced via a process referred to as contact simplification.

Collisions with Deformable Terrains can cause high contact generation time consumption. Simplify the colliding collision shapes.

High Time Consumption in "stepExtensions"

Fluid Interaction

Using fluid interaction is likely the source of this problem. If a lot of rigid bodies or complex triangle meshes are used in a fluid, that could be the cause of your slowdown in performance. Simplifying your fluid collision geometries can solve this issue.

Earthwork Systems

Earthwork systems simulations could be the cause of the issue. Using a larger cell size for Earthwork Zones and Soil Bins could be a solution to this performance problem.

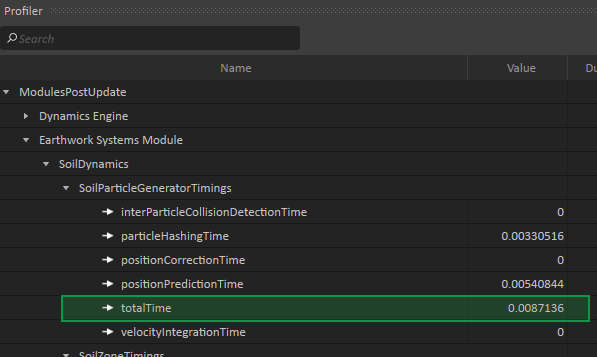

To confirm that the soil particle simulation is the cause of the slowdown, consult the detailed soil dynamics timings under ModulesPostUpdate > Earthwork Systems Module > SoilDynamics.

Note that the displayed timing measurements are in milliseconds. For more potential performance issues in soil simulation, consult Finding Bottlenecks in Earthwork Simulations.

Custom Extensions

If you have written your own IDynamics extension, your code could be the source of the issue.

High Time Consumption in "intersectSubscribers"

This could be related to an intense use of sensors and triggers.

Alternatively, if you wrote an extension which uses an implementation of the class VxUniverse::IntersectSubscriber, it is possible that the time is spent in this implementation.

Finding Bottlenecks in Earthwork Simulations

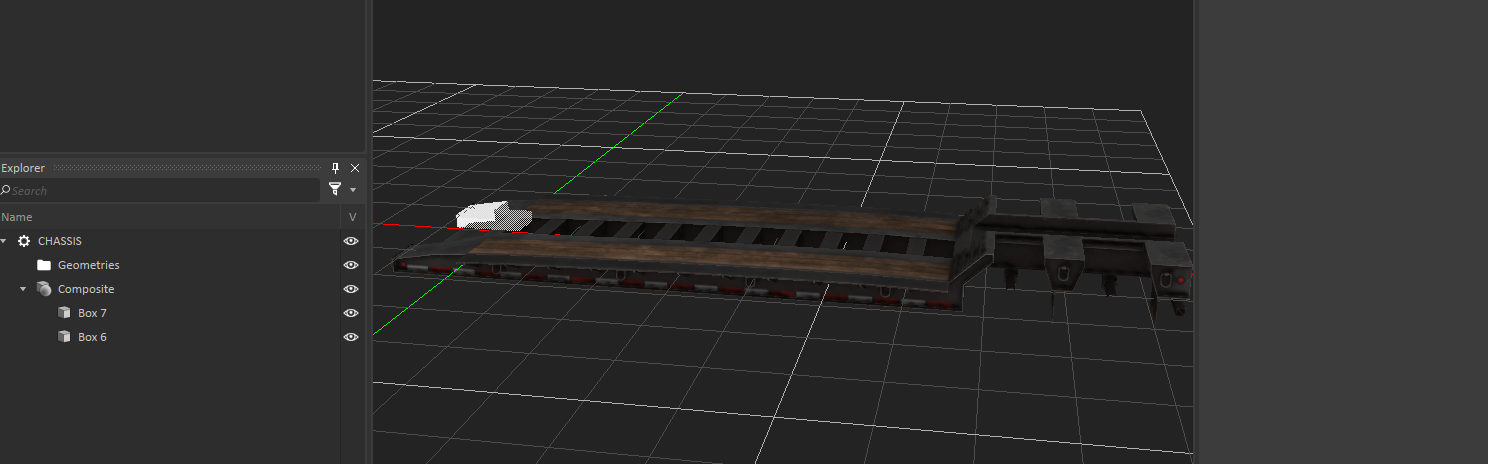

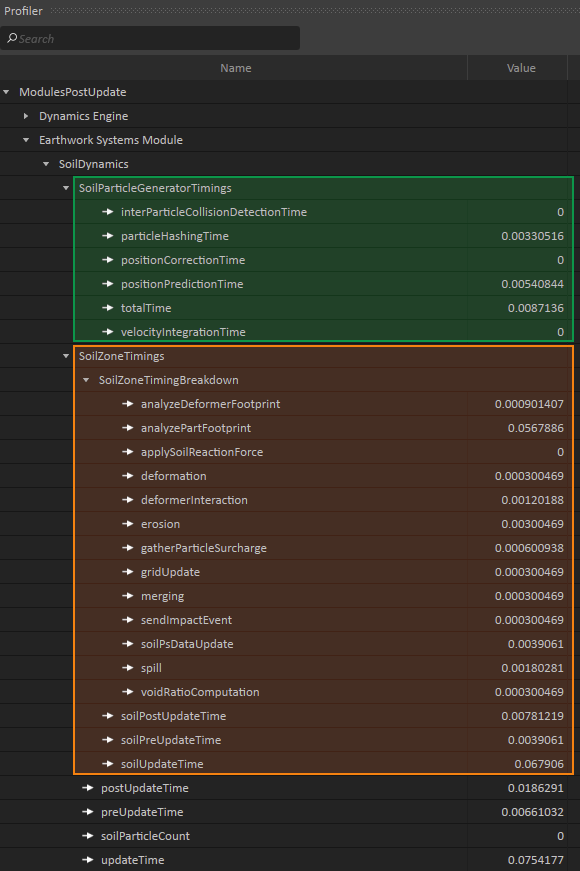

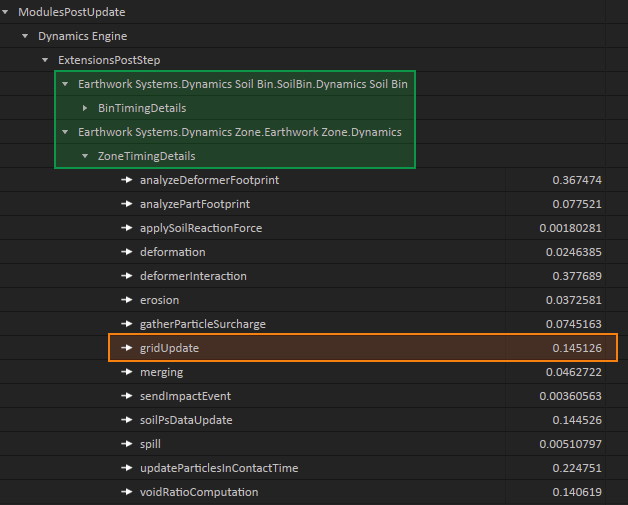

Additional, specialized simulation components are used in Earthwork Systems. These simulation components are enabled by adding the Earthwork Systems module to your Application Setup (.vxc) file. For the purpose of tracking time consumption of these components, the Earthwork Systems module exposes additional, focused timing measurements ranging from soil particle simulation time to the time it takes to simulate soil erosion on the diggable soil zones. This profiling information can be found in the Profiler under ModulesPostUpdate > Earthwork Systems Module > SoilDynamics, as seen below.

The measurements are grouped in "time spent on soil particle simulation" (highlighted in green in the screenshot) and "time spent on updating the diggable soil zones" (highlighted in orange). The displayed values are given in milliseconds.

If the time consumption of certain simulation components from this list become too high, certain remedies can be applied to reduce the workload and speed up the simulation. Below is a list of common bottlenecks and the corresponding solutions.

High Time Consumption in "SoilParticleGeneratorTimings > totalTime"

This case indicates that there are probably too many particles in the simulation for the simulation to run smoothly on the given hardware. The soil particle simulation is parallelized and can be sped up by using faster processors with more cores. If this is not an option, you can either limit the number of particles via the Soil Materials Extension, or use smaller particle sizes.

High Time Consumption in "SoilZoneTimings > SoilZoneTimingsBreakdown > gridUpdate"

This likely indicates that an Earthwork Zone in the simulation is rather large and has the Output Mass parameter selected. If possible, deselect Output Mass; this will eliminate the bottleneck in gridUpdate. At the same time, this will no longer provide the mass of the Earthwork Zone as an output field. As an alternative, use a Soil Mass Sensor to measure the mass in a smaller area of interest. Otherwise, the cell size of the Earthwork Zone or Soil Bin which is the cause of the bottleneck can be reduced to lower the time consumption. In order to find the Earthwork Zone or the Soil Bin which is causing the slow down, it is possible to consult detailed timings per zone or bin. These timings can be found under the post update timings of the dynamics module as shown below.

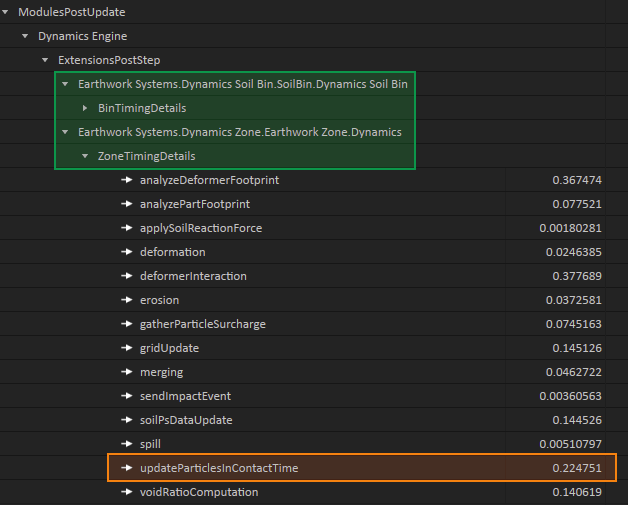

High Time Consumption in "updateParticlesInContactTime" (of a specific Earthwork Zone or Soil Bin)

It is possible that significant time is spent to produce the list of particles which are traveling on an Earthwork Zone or a Soil Bin. This bottleneck can be identified by inspecting the detailed timings of the individual zones or bins as shown below.

If the updateParticlesInContactTime is found to be elevated, the Output Particles parameter on the corresponding zone or bin can be deselected to disable the calculation of this particle list. This will completely remove the time spent. The consequence of this modification is that the particles traveling on the corresponding soil surface can no longer be wrapped by the graphical height field. This is not an issue if the Screen Space Mesh option in the Soil Particles Extension is used for displaying simulated soil particles.